Edge-Winding

Edgewise winding by REO

Advantages of edge winding technology

Up to 10% reduction in weight

“This edge-winding technology is an innovation from our development team, which is constantly researching the latest technologies and always comes across new approaches as a result. We recognised the opportunities that came with this new winding technology and have been able to start small scale or serial production since 2020, offering our customers extremely fast delivery times. In particular, the impressive cooling feature in the N CNW series is enabled through the single-layer structure with alternative materials and means insulation material often becomes unnecessary. This has two benefits, on one hand, this results in smaller dimensions and lower weight, and on the other, the product is more durable and there are more application possibilities compared to traditional winding technologies.”

Sven Reimann

Advancing Cooling and Efficiency

With the introduction of the latest generation of N CNW series chokes and filters, REO is further advancing the use of EDGE winding technology. With increased effectiveness and simultaneously lower weight, the new series with vertical winding exhibit extremely efficient cooling due to their single-layer construction – especially with forced cooling.

Due to the improved cooling, aluminum conductors can be used as a replacement for copper conductors, depending on the design. In combination with automated production, manufacturing costs have therefore been further reduced.

The lower weight and smaller dimensions are possible thanks to the reduction of skin and proximity losses. EDGE winding is particularly suitable for semiconductors based on new materials such as silicon carbide (SiC) and gallium nitride (GaN).

The near-elimination of insulating materials enhances component lifespan.

The REO experts will be happy to answer your questions at any time.

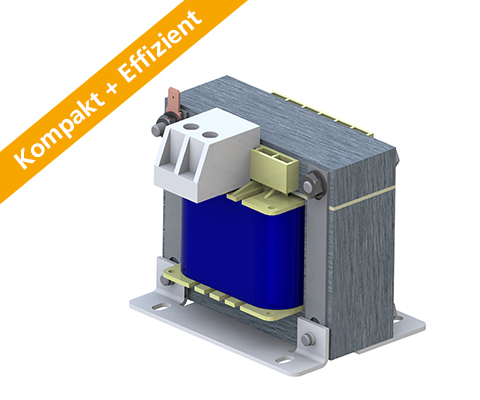

Product highlight:

Mains choke N CNW 901

The new series not only scores points for its faster delivery time, but also for its resource conservation and increased efficiency.

Reduce mains interference – save up to 20% on energy costs. A mains choke relieves the supply network by compensating for harmonic reactive power.

Technologies from REO

REO: A reliable partner

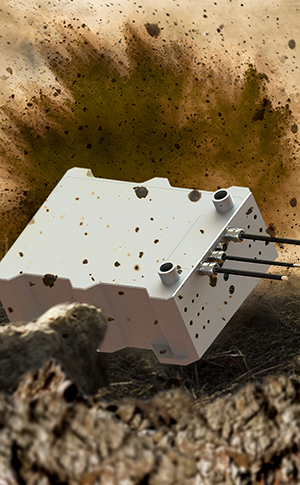

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.