REOVIB 2.0

REOVIB 2.0

At the start of the REOVIB 2.0 project, our development goal was as purist as it was ambitious: we would launch the world’s most modern and future-proof control portfolio for vibratory conveyor technology. This ambitious goal of defining the global competition with a new benchmark required the combined expertise of the REO specialists. This is why our best and most visionary developers, planners, designers and product specialists from a wide range of countries are working together to develop the REOVIB 2.0 portfolio. In collaboration with the experts from REO Digital Connect 4.0, a comprehensive requirements profile was implemented to enable the new control unit to be used both in established production environments and in fully digitalised production processes.

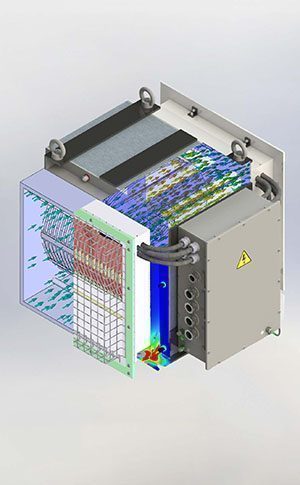

Competence in development and production – REOVIB MFS 368 made by REO

With an input voltage ranging from 99 to 264 volts, a constant 205-volt output voltage, and comprehensive certification, the new REOVIB MFS 368 is ready for use worldwide. Where several conveyors used to be used, a REOVIB MFS 368 is now sufficient. Thanks to automatic control, the conveying performance remains constant; this is entirely independent of the place of use, changing mechanical loads, or the wear of springs. There is no need for manual adjustment and readjustment, and worry-free continuous operation is possible.

“From the beginning of the development of the REOVIB MFS 368, it was important to our developers and technicians to keep a close eye on the current practical requirements of the industry. In addition, to do justice to future developments in the field of Industry 4.0, we worked closely with REO Digital Connect 4.0 – a specialised start-up of REO in digitisation and device communication with a view to Industry 4.0. With the REOVIB MFS 368, REO AG has launched the most modern and future-proof control system for vibratory conveyor technology on the market.”

André Kurzbach

The REO experts will be happy to answer your questions at any time.

André Kurzbach

Member of the Executive Board and Sales Director at REO AG

In use worldwide

Experience reports from real production sites show how different the production conditions are worldwide: the new product must function in the USA, Europe, China or India within the framework of the regionally significantly different production conditions, without any problems and with low maintenance, e.g. completely independent of the frequency of the electrical network. Numerous built-in protection mechanisms, interfaces, and user functions enable this global use. For example, the devices can be optionally equipped with fieldbus interfaces and are also optionally available as versions with UL/CSA certification, which enables uncomplicated use without effort and testing in plants in the USA and Canada.

However, despite the significantly increased performance, the new housing design should hardly differ from the previous devices. The new REOVIB should be able to replace the old devices 1:1 without any problems. The biggest innovations are therefore inside. The REOVIB 2.0 is ready for IIoT (Industrial Internet of Things) and will in the future support the REONET DL (Devices-Link) and REONET CT (Configuration-Tool) hardware and software developed by REO.

Technologies from REO

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.