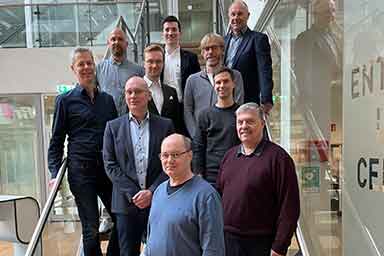

Promoting Young Talent through the Germany Scholarship Program

On November 19, 2025, the time had come once again: during a festive ceremony at the University of Wuppertal, this year’s Germany Scholarships were awarded. A total of 81 sponsors from the region are supporting students this year who stand out not only for their excellent academic achievements but also for their social commitment, social responsibility or special personal accomplishments. The University of Wuppertal has been successfully involved in the Germany Scholarship program for 15 years, and REO AG has been one of its active sponsors for eight years now – driven by the goal of supporting tomorrow’s skilled professionals and leaders and thereby strengthening the regional economy in the long term. For the third year in a row, REO is supporting Mr. Marius Benedikt Breuer, who, after successfully completing his bachelor’s degree in electrical engineering, is now pursuing his master’s studies with great dedication. We warmly congratulate Mr. Breuer and look forward to continuing to accompanying him on his path in the coming year. Photo: ©Paco_Calderon

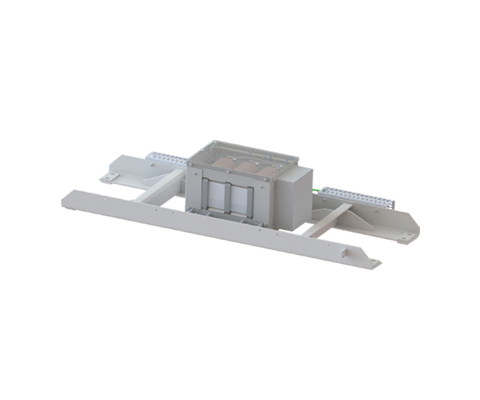

Railway Transformer NTT 400 D

On-board power supply transformer for roof mounting Description The REO on-board power supply transformer NTT 400 D is designed for on-board power supplies that are fed by the on-board power converter (BNU). The transformer NTT 400 D refers to the complete, ready-to-operate unit with transformer, support frame, and housing. The transformer is used for voltage adaptation and galvanic isolation of the pulse-width modulated DC link voltage and the consumers of the on-board power supply system. A suitable sine filter must be connected between the transformer and the inverter. The secondary-side load of the isolation transformer can be switching devices, rotating machines, ohmic loads, and semiconductor converter devices. The transformers are designed for use in vehicles in AC or DC networks (in inverter operation) within containers. This ensures that REO transformers are optimally configured for your application. Maximum service life, cost-benefit optimization, and safety are the key priorities in our development. Customized complete solutions On-board power supply transformers can be custom-designed. Are you interested in this product? Please contact us! In addition to standardized components for use in converters, REO offers customized products – as a single component or as a complete solution in a container. The benchmark in railway technology is the availability and safety of passengers. Here, REO offers special solutions that are developed step by step in close cooperation with the customer. Advantages Vibration and shock tested according to DIN 61373 Cat 1 Class B High efficiency Low no-load losses Reduced stray field Low noise emission Weight-optimized High mechanical load capacity Cooling ON Pollution degree PD4 Various power classes Technical data Rated power: 10000 – 30000 VA Input voltage: 3×440 V Power: 10-30 kVA Nominal voltage: Primary: Rated voltage: (Normal operation): 3×440 Veff 60 Hz Rated voltage: (External supply): 3×400 Veff 50 Hz Rated voltage: (Reduced operation): 3×345 Veff 47 Hz Secondary: Voltage: 3×230 Veff Operating temp.: -25°C … +55°C (optional +75°C) Humidity: max 95% Pollution degree: PD4 Insulation class: F/H Test voltage: EN 50124 / EN 60310 Vibration resistance: Cat.1 Class A/B according to EN61373 Voltages: 24 / 42 / 110 / 230 / 400 / 690 Volt (Optional) Switching group: Optional Type Power [kVA] Total weight [kg] Copper weight [kg] Efficiency [%] UK [%]* NTT 400 U/15.0 15.0 96 29 97.1 2.6 NTT 400 U/20.0 20.0 126 36 97.4 2.3 NTT 400 U/25.0 25.0 150 51 97.5 2.5 NTT 400 U/30.0 30.0 175 57 97.8 2.1 Dimensions in mm Type L B H N1 N2 N3 D Mass [kg] NTT 400 U/15.0 1800 581 376 1717 363 65 13×26 192 NTT 400 U/20.0 1800 581 376 1717 363 65 13×26 219 NTT 400 U/25.0 1800 581 376 1717 363 65 13×26 247 NTT 400 U/30.0 1800 581 376 1717 363 65 13×26 267

Air Choke Ld 220

Air choke with aluminium copper/disc winding DESCRIPTION Air reactors are particularly used where high inductive linearity is required. Due to their relatively simple mechanical structure, they are not only compact, but also very robust. With our expertise, the REO air reactors perform to the required standard, even in the most arduous conditions. REO Mix & Match principle With REO Mix & Match you can choose from a wide range of of options – combine the various options in order to always get the best product for your application. REO is able to offer different designs and winding techniques, a variety of conductor materials and structures. Depending on the specific requirements, we are able to produce an optimal solution by combining these parameters to provide the perfect solution. Optional Layer winding/Disc winding Aluminium, Copper or aluminium + copper Protections: Paint coating, protective coating, housing or REO Xtreme Cooling fan/unit Sensors: Switch NO / NC, PT100, NTC, PTC ADVANTAGES No saturation Wide range of material selection Special protective coating High linearity L (i) Very good mechanical strength No hysteresis Optimal weight by forced air cooling Directional air flow through GRP conduits Very efficient liquid cooling option (waveguide) Can be used almost anywhere PTC Technical Data Frequency of the current: DC and AC Tolerances: + 10 / – 10 %, + 5 / – 5 % Taps: By default, no taps (available on request) Insulation: F or H Cooling method and cooling liquid according to IEC 60310: AN, AF or WF Test voltage: up to 12kV 60s 50Hz, up to 25kV 1,2/50µs Mounting: Suspended, vertical or horizontal Mechanical strength, mechanical simulation (FEM): EN 12663 Shock – and vibration stress: IEC 61373 Kat. 1 Kl. B Rated current: 200 – 700 A Inductance: 0,5 – 4 mH Type Inductance (mH) Cooling 3 m/s Cooling 5 m/s Cooling 8 m/s I [A] magn. Energy [J] P [kVA] at 20°C I [A] magn. Energy [J] P [kVA] at 20°C I [A] magn. Energy [J] P [kVA] at 20°C LD 220/200/0,5 0,5 200 10 0,7 250 15,6 1,1 300 22,5 1,6 LD 220/400/0,5 0,5 400 40 1,8 500 62,5 2,9 600 90 4,2 LD 220/700/0,5 0,5 700 122,5 2,4 500 62,5 2,9 600 90 4,2 LD 220/200/1 1 200 20 1,1 250 31,3 1,7 300 45 2,4 LD 220/400/1 1 400 80 2,8 500 125 4,4 600 180 6,3 LD 220/700/1 1 700 245 3,8 850 361,3 5,5 100 5 7,7 LD 220/200/2 2 200 40 1,7 250 62,5 2,6 300 90 3,7 LD 220/400/2 2 400 160 4,4 500 250 6,9 600 360 10 LD 220/700/2 2 700 490 5,7 850 722,5 8,4 1000 1000 11,6 LD 220/200/4 4 200 80 2,5 250 125 3,9 300 180 5,6 LD 220/400/4 4 400 320 6,9 500 500 10,8 600 720 15,6 LD 220/700/4 4 700 980 8,7 850 1445 12,8 1000 2000 17,7 Dimensions in mm Type B [mm] H [mm] T [mm] Copper [kg] Weight [g] LD 220/200/0,5 250 250 180 11,4 16 LD 220/400/0,5 350 350 180 20,9 29 LD 220/700/0,5 400 400 370 74,8 86 LD 220/200/1 300 300 220 17,6 33 LD 220/400/1 400 400 220 32,5 37 LD 220/700/1 400 400 450 116 124 LD 220/200/2 350 350 230 26,7 40 LD 220/400/2 400 400 310 51,4 87 LD 220/700/2 450 450 490 175 182 LD 220/200/4 400 400 250 40,2 54 LD 220/400/4 420 420 400 80,3 97 LD 220/700/4 500 500 570 267 301

AC MAGNET REOVIB WE 131

Packaging and weighing industry for feeding and sorting processes; automation processes when using drives with vibrating magnets.

REOVIB Accelerometers SW

Sensor for measuring accelerations in the range of 0… 35 g (frequency dependent)

REO DC-Chokes in New Berlin Subways

The unveiling of Stadler’s new JK series subway train marks a significant step in the development of the Berlin rail network. Compared to the trains that are over three decades old, the new train represents a leap into a new technological age.

Mechanical Engineering Network Bergisch Land

AI-based production planning

The Vibratory Feeding and Power Electronics Division of REO AG in Solingen is a participant in the research project KIbaroP, AI-based robust production planning, of the FIR at RWTH Aachen University.