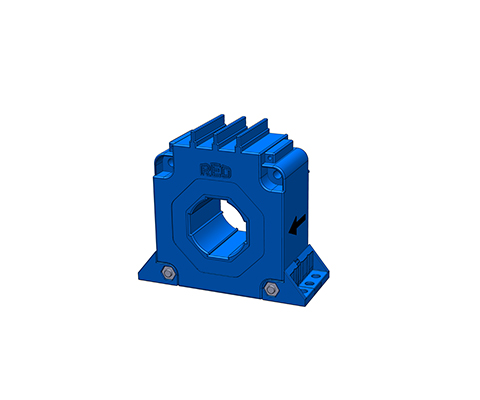

Air choke with aluminium copper/disc winding

DESCRIPTION

Air reactors are particularly used where high inductive linearity is required. Due to their relatively simple mechanical structure, they are not only compact, but also very robust.

With our expertise, the REO air reactors perform to the required standard, even in the most arduous conditions.

REO Mix & Match principle

With REO Mix & Match you can choose from a wide range of of options – combine the various options in order to always get the best product for your application.

REO is able to offer different designs and winding techniques, a variety of conductor materials and structures. Depending on the specific requirements, we are able to produce an optimal solution by combining these parameters to provide the perfect solution.

Optional

- Layer winding/Disc winding

- Aluminium, Copper or aluminium + copper

- Protections: Paint coating, protective coating, housing or REO Xtreme

- Cooling fan/unit

- Sensors: Switch NO / NC, PT100, NTC, PTC

ADVANTAGES

- No saturation

- Wide range of material selection

- Special protective coating

- High linearity L (i)

- Very good mechanical strength

- No hysteresis

- Optimal weight by forced air cooling

- Directional air flow through GRP conduits

- Very efficient liquid cooling option (waveguide)

- Can be used almost anywhere PTC

- Frequency of the current: DC and AC

- Tolerances: + 10 / – 10 %, + 5 / – 5 %

- Taps: By default, no taps (available on request)

- Insulation: F or H

- Cooling method and cooling liquid according to IEC 60310: AN, AF or WF

- Test voltage: up to 12kV 60s 50Hz, up to 25kV 1,2/50µs

- Mounting: Suspended, vertical or horizontal

- Mechanical strength, mechanical simulation (FEM): EN 12663

- Shock – and vibration stress: IEC 61373 Kat. 1 Kl. B

- Rated current: 200 – 700 A

- Inductance: 0,5 – 4 mH

| Type | Inductance (mH) | Cooling 3 m/s | Cooling 5 m/s | Cooling 8 m/s | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| I [A] | magn. Energy [J] | P [kVA] at 20°C | I [A] | magn. Energy [J] | P [kVA] at 20°C | I [A] | magn. Energy [J] | P [kVA] at 20°C | ||

| LD 220/200/0,5 | 0,5 | 200 | 10 | 0,7 | 250 | 15,6 | 1,1 | 300 | 22,5 | 1,6 |

| LD 220/400/0,5 | 0,5 | 400 | 40 | 1,8 | 500 | 62,5 | 2,9 | 600 | 90 | 4,2 |

| LD 220/700/0,5 | 0,5 | 700 | 122,5 | 2,4 | 500 | 62,5 | 2,9 | 600 | 90 | 4,2 |

| LD 220/200/1 | 1 | 200 | 20 | 1,1 | 250 | 31,3 | 1,7 | 300 | 45 | 2,4 |

| LD 220/400/1 | 1 | 400 | 80 | 2,8 | 500 | 125 | 4,4 | 600 | 180 | 6,3 |

| LD 220/700/1 | 1 | 700 | 245 | 3,8 | 850 | 361,3 | 5,5 | 100 | 5 | 7,7 |

| LD 220/200/2 | 2 | 200 | 40 | 1,7 | 250 | 62,5 | 2,6 | 300 | 90 | 3,7 |

| LD 220/400/2 | 2 | 400 | 160 | 4,4 | 500 | 250 | 6,9 | 600 | 360 | 10 |

| LD 220/700/2 | 2 | 700 | 490 | 5,7 | 850 | 722,5 | 8,4 | 1000 | 1000 | 11,6 |

| LD 220/200/4 | 4 | 200 | 80 | 2,5 | 250 | 125 | 3,9 | 300 | 180 | 5,6 |

| LD 220/400/4 | 4 | 400 | 320 | 6,9 | 500 | 500 | 10,8 | 600 | 720 | 15,6 |

| LD 220/700/4 | 4 | 700 | 980 | 8,7 | 850 | 1445 | 12,8 | 1000 | 2000 |

|

| Type | B [mm] | H [mm] | T [mm] | Copper [kg] | Weight [g] |

| LD 220/200/0,5 | 250 | 250 | 180 | 11,4 | 16 |

| LD 220/400/0,5 | 350 | 350 | 180 | 20,9 | 29 |

| LD 220/700/0,5 | 400 | 400 | 370 | 74,8 | 86 |

| LD 220/200/1 | 300 | 300 | 220 | 17,6 | 33 |

| LD 220/400/1 | 400 | 400 | 220 | 32,5 | 37 |

| LD 220/700/1 | 400 | 400 | 450 | 116 | 124 |

| LD 220/200/2 | 350 | 350 | 230 | 26,7 | 40 |

| LD 220/400/2 | 400 | 400 | 310 | 51,4 | 87 |

| LD 220/700/2 | 450 | 450 | 490 | 175 | 182 |

| LD 220/200/4 | 400 | 400 | 250 | 40,2 | 54 |

| LD 220/400/4 | 420 | 420 | 400 | 80,3 | 97 |

| LD 220/700/4 | 500 | 500 | 570 | 267 | 301 |