Vibratory feeding

Frequency Inverters – Vibratory Magnets – Sensors – Measuring Devices

Vibratory feeding technology from REO

Vibratory conveyor technology is used as a specialised area of industrial conveyor technology for feeding various conveyed goods in assembly, packaging and filling machines. The areas of application are extremely diverse, for example in industrial assembly automation, in pharmaceutical packaging systems, in industrial conveyor technology and in food processing and packaging.

The complete systems from REO in the combination of REOVIB control units and the matching REOVIB acceleration sensors and vibration magnets, which are available in different versions, e.g. also in a powder-coated version with FDA approval, have proven to be the ideal solution in numerous areas of application.

For controlled operation, every vibratory feeder requires a control unit. Under the REOVIB brand, REO offers various series of control units to meet all requirements for the feeding characteristics of a vibratory feeder and the flow of conveyed parts. These series include a wide range of control units, from simple controls that provide variable voltage for the magnet using triacs or thyristors in phase-angle control mode, to frequency inverters that generate any desired drive frequency and amplitude for the vibratory feeders.

The device versions range from PCB designs for integration into custom enclosures or control cabinets, to control cabinet installation devices for mounting rails or plates, and even self-contained enclosed versions with protection classes from IP54 to IP65. Via control inputs and outputs, individual devices can be linked to systems that operate complete feeding stations. Connections to higher-level control systems can be established via analog signals or through fieldbus couplings such as Profibus, CAN-Bus, EtherCAT, EtherNet/IP, and ProfiNet. Optionally, many versions are also available with UL/CSA certification.

Media Center

The new Media Center for vibratory feeding technology offers a variety of useful resources. Visitors can find videos of operating instructions and interface changes, as well as all operating manuals and STEP data for REOVIB products.

REOVIB MFS Frequency Inverters

The REOVIB MFS series for vibratory feeder drives generate a drive voltage and frequency for the vibratory feeder that are independent of the frequency and magnitude of the connected mains voltage.

Any desired drive frequencies for the vibratory conveyor that are within the device frequency ranges may be set. The digitally controlled devices are operated via an

LED or LCD display.

REOVIB Smart Phase-Angle Controls

The REOVIB SMART series includes phase-angle control units for use in vibratory feeding technology applications.

The devices offer the most important functions for use in vibratory feeding technology, thus providing a cost-effective solution for controlling vibratory feeders – and that in a high-quality design.

REOVIB RTS Phase-Angle Controls

The devices provide an increased level of adjustability for a variety of functions such as the soft-start setting, as well as additional control functions such as the implementation of a level scanning system/overflow controller.

The devices are available in a variety of protection classes from IP00 to IP54 – you therefore have the opportunity of selecting the control device from the REOVIB RTS series that has been optimally designed for the corresponding application.

REOVIB MTS Programmable Phase-Angle Controls

The REOVIB MTS series includes single-, dual-, and triple-channel control units for vibratory feeder drives. These are phase-angle controls with a triac as the power element.

Consequently, the vibration frequency of the feeding devices can be equal to or twice the mains frequency of the input voltage.

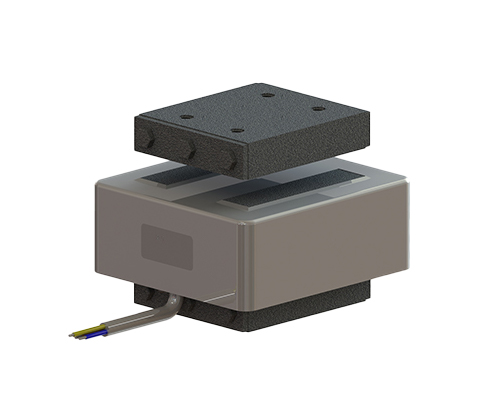

REOVIB AC Magnets

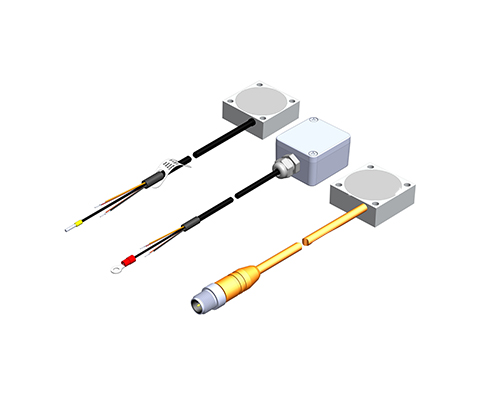

Sensors

REOVIB acceleration sensors contain a piezoelectric acceleration element with a downstream amplifier. The accelerations are detected by the piezoelectric element and converted into a voltage proportional to the acceleration.

The sensors can be used, for example, for regulating and monitoring feeder drives, for detecting mechanical vibrations, or for monitoring acceleration or braking effects.

Measuring equipment

Custom Development

Custom-developed, technically suitable solutions for your application.

We analyze your actual technical requirements and develop product solutions capable of standardization.

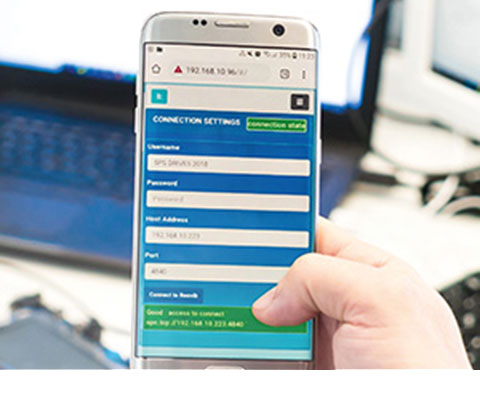

IIOT-Ready

Industry 4.0 is the strategy for the comprehensive digitalisation of industrial production. Digital technologies and processes enable completely new approaches…