Analysis and test methods

Quality through testing

Analysis and test methods

Measurement and test methods

To achieve the highest quality and so that new developments can be driven forward, extensive quality tests, quality assurance measures, and the application of highly developed analytical methods have always been the focus of product development and improvement. An extensive repertoire of techniques, tests, and inspections ensures we meet the highest quality and safety standards. For this purpose, a separate service department deals exclusively with the technologies and test procedures of the components and continuously optimises the processes and products. Compliance with various standards and holding awarded certificates by well-known institutions demonstrate REO’s high-quality standards. REO complies with DIN EN ISO 9001:2008, DIN EN 60310/VDE Part 420/IEC 60310 and EN 15085-1 to -5, among others. Furthermore, many REO developments are patented, ensuring that our engineers’ inventions and innovations are legally protected.

Examples of our checks and tests:

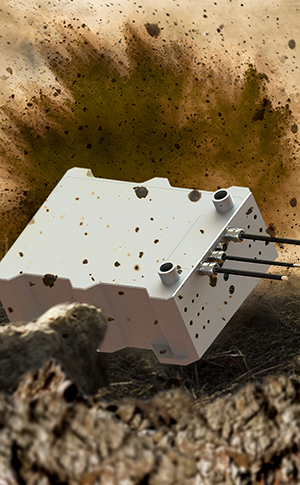

- Shock and vibration tests

- Salt spray tests

- Cold and heat tests

- G-strength test

- Water tests

- Fire protection tests

Quality inspection at your sites

Do you want to test your components in the field? REO offers a broad portfolio of products for test benches and test equipment for electrical components. From individual components, resistive, inductive and capacitive loads to complete test systems for converter tests are available. We manufacture all components at our German sites in compliance with the highest quality and safety standards.

The REO experts will be happy to answer your questions at any time.

Technologies from REO

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.