Liquid cooling

optimal temperature behavior with better performance and longer product life

Liquid cooling

Effective cooling in high ambient temperatures

While air cooling often has limitations, particularly for compact components, REO offers a range of inductive and resistive components equipped with advanced water cooling systems. This ensures optimal temperature control, enhancing performance and extending component lifespan.

This ensures optimal temperature control, enhancing performance and extending component lifespan.

The higher investment costs for water cooling technology are offset by a variety of advantages when compared with a air cooling based system:

- High efficiency and low noise level

- Compact design

- Effective cooling in high ambient temperatures

- Very low housing temperature

- Extended service life under normal operating conditions

- Consistently high performance with efficient heat dissipation

- only method that permits cooling below the ambient air temperature

- Water-cooled systems are especially beneficial for industrial applications requiring low surface temperatures, such as wood and textile processing or ATEX areas

The REO experts will be happy to answer any questions you may have at any time.

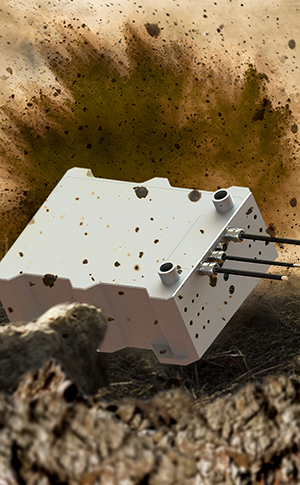

Product Highlight: REOHM Resistor Series D 330

Technologies from REO

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.