Measurements

Measurements

Measurement of sources of error in the field of power quality

Electromagnetic compatibility (EMC) is an essential goal in the planning and operation of electrotechnical systems. All components should work safely and smoothly with each other and, if at all, only intentionally influence each other. Unfortunately, this is often extremely difficult to achieve in practice. To effectively deal with power quality problems such as harmonics, voltage dips or reactive power, the sources of the problem must first be analysed and measurements evaluated. REO provides the necessary portable or permanently installed measuring instruments and collects measurement data, if required, for up to one year. Our qualified specialist staff evaluates the recorded measurements and can thus configure the appropriate REO Power Quality product for you individually.

Our test fields

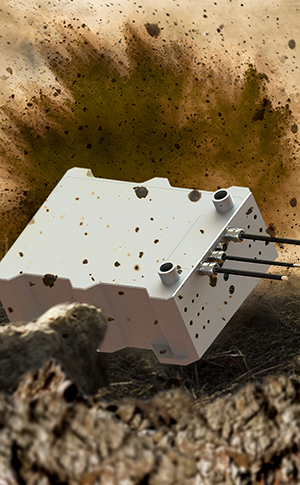

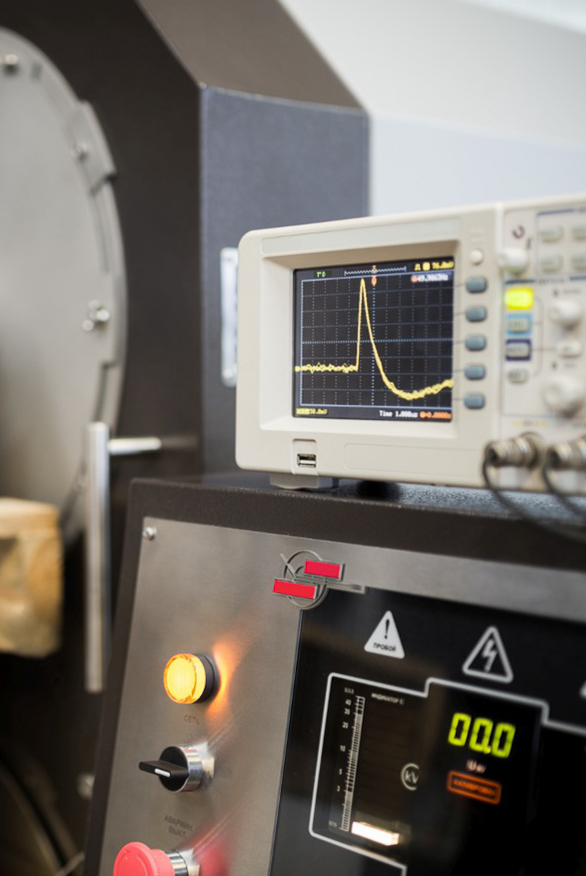

Quality assurance is a top priority at REO. That is why we operate electrical test facilities at all our locations worldwide as part of our extensive product control. Using state-of-the-art measurement technology ensures the highest quality and functionality of our products.

According to the ‘everything from a single source’ principle

- Exact discussion of the problem with the help of EMC long-term measurements (over several months) with the help of state-of-the-art REO devices

- Consistent compliance with current norms and standards

- Customer-specific design of a product or a product combination precisely for the requirements identified

- In-house development and production of the system solution

- Installation and service on-site by competent REO employees

Which product solution is right for me?

A product solution tailored to your needs is determined with the help of long-term EMC measurements (REO service). These measurements show details over several months or even a fraction of a second. Depending on your specifications, Total Harmonic Distortion (THDI value), legal standards and specifications, there are a variety of options:

- If, for example, a THDI value of 35% is specified, a mains choke is suitable. This solution’s advantage is clearly its relatively inexpensive implementation.

- A combination of a mains choke and an appropriate filter can be used, with a THDI specification of 20%.

- The REOWAVEpassive is the optimal solution for a low THDI value of less than 5%, provided that a B6 converter topology is utilised.

The REO experts will be happy to answer your questions at any time.

Technologies from REO

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.