Simulations

Simulations

Shorter development times - Lower development costs - Optimised products

REO products are used worldwide and, in some cases, every day under the toughest conditions. Whether it’s -30°C in the mountains of the Rocky Mountains in Canada or +40°C in the Nevada deserts in the USA, REO products are known to be relied on even in the most adverse conditions.

To guarantee this, we apply the highest standards and requirement criteria in manufacturing our products and begin extensive testing and simulation in the early phase of their development. The focus is on your components’ specific electrical, mechanical and environmental requirements.

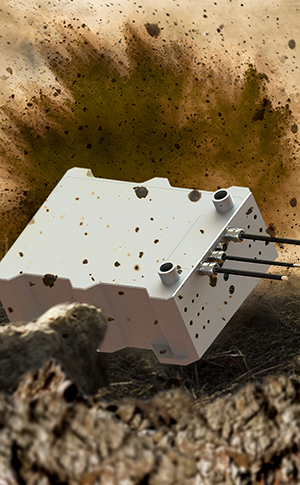

To save material and resources and to shorten development times, i.e. ultimately to minimise costs, we use state-of-the-art computers and software and carry out simulations, e.g. about temperature changes, heat conduction and heat radiation. But also service life calculations of screws and weld seams or investigations of the effects of cyclic loads can be carried out by modern engineering programs without having produced a single prototype.

Of course, it is just as important to quickly recognise the weaknesses without having produced a single prototype. For example, we carry out EMC simulations on chokes to determine the size of the magnetic stray field and thus the applicability or the required shielding measures to protect other electrical devices.

Thanks to these targeted analyses, we can respond to your requirements very individually and promptly, reduce development times and corresponding development costs and ultimately significantly increase the quality of our products.

The REO experts will be happy to answer your questions at any time.

Technologies from REO

REO: A reliable partner

As one of the world’s leading manufacturers of inductive components, REO specialized early on in the challenge of EMC problems in frequency converter-controlled drive systems. In cooperation with manufacturers of drive systems and mechanical engineering companies, we have innovatively advanced this development over the last four decades. Our EMC solutions are specially tailored to these drive systems. Thanks to our comprehensive vertical integration and expertise in filtering such systems, which is bundled in our own development center, we can offer our customers the best possible EMC solutions. In addition to EMC tests and tests under extreme environmental conditions, we also carry out shock and vibration tests in our own laboratory.

For particularly demanding projects, we at REO develop customized solutions in close cooperation with our customers. Our many years of experience and constant innovation, inspired by the diverse requirements of industries such as rail technology and wind energy, enable us to create the ideal tension for our customers’ products.